PhD defense

Written by Asger Bjørn Jørgensen, 2019-06-15

After almost three years of work the final result is this thesis

On Thursday the 27th of June 2019 there will be a public defense my PhD thesis titled "Packaging of Wide Bandgap Power Semiconductors using Simulation-based Design"

The defense will be held in the main auditorium at

Deparment of Energy Technology

Aalborg University

Pontoppidanstræde 111

9220 Aalborg Øst, Denmark

The thesis is available for download on the AAU research portal.

CIPS18 conference

Written by Asger Bjørn Jørgensen, 2018-04-08

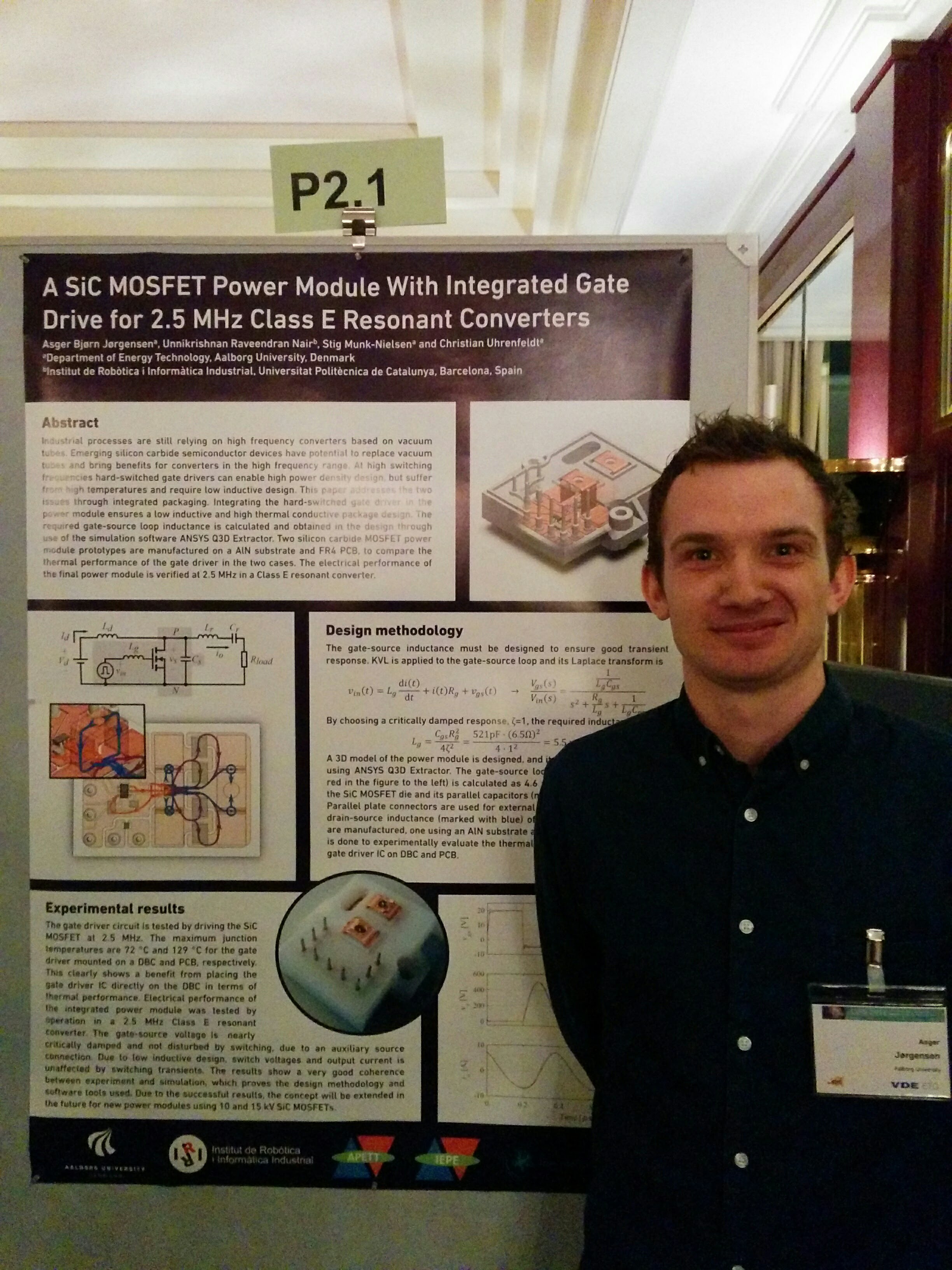

I had a great experience at the Conference on Integrated Power Electronics Systems (CIPS18) held in Stuttgart, Germany from the 20.-22. of March 2018.

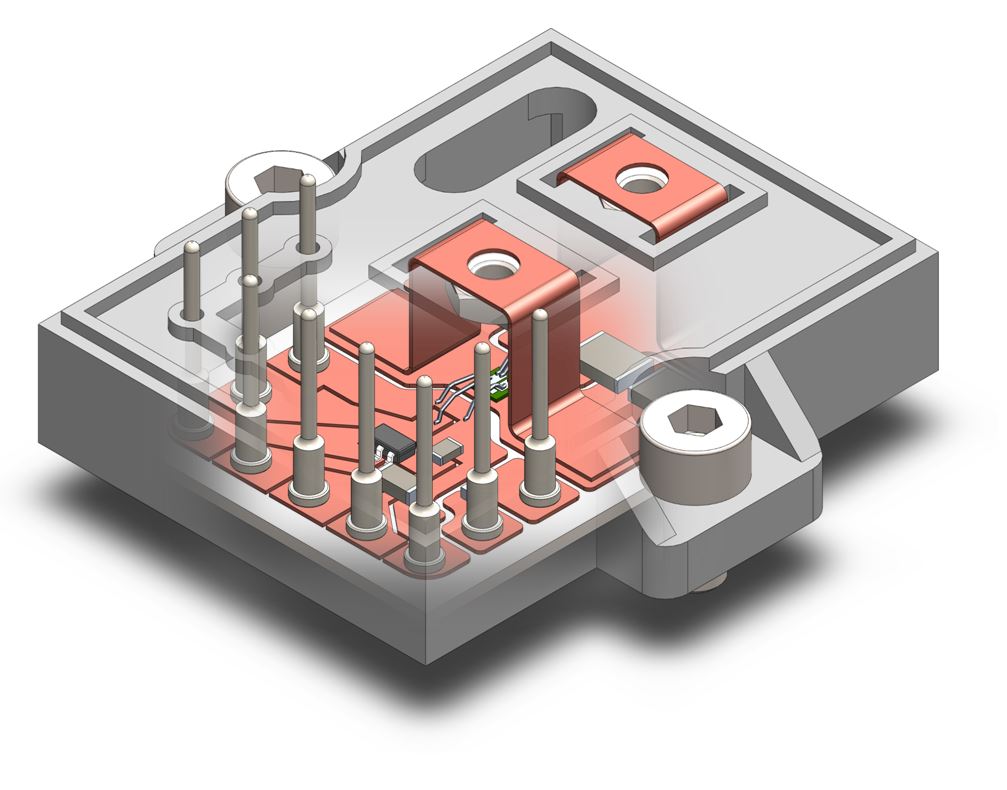

I presented my paper on the design and experimental tests of a SiC MOSFET based power module with an integrated gate driver circuit, which enables it to operate at 2.5 MHz. The power module was tested in a Class E resonant converter application, which means that the parallel capacitance required to ensure zero voltage switching is also integrated in the power module itself.

The paper is available IEEE Xplore. If you wish to discuss the paper, please do not hesitate to contact me.

EPE17 conference

Written by Asger Bjørn Jørgensen, 2017-09-18

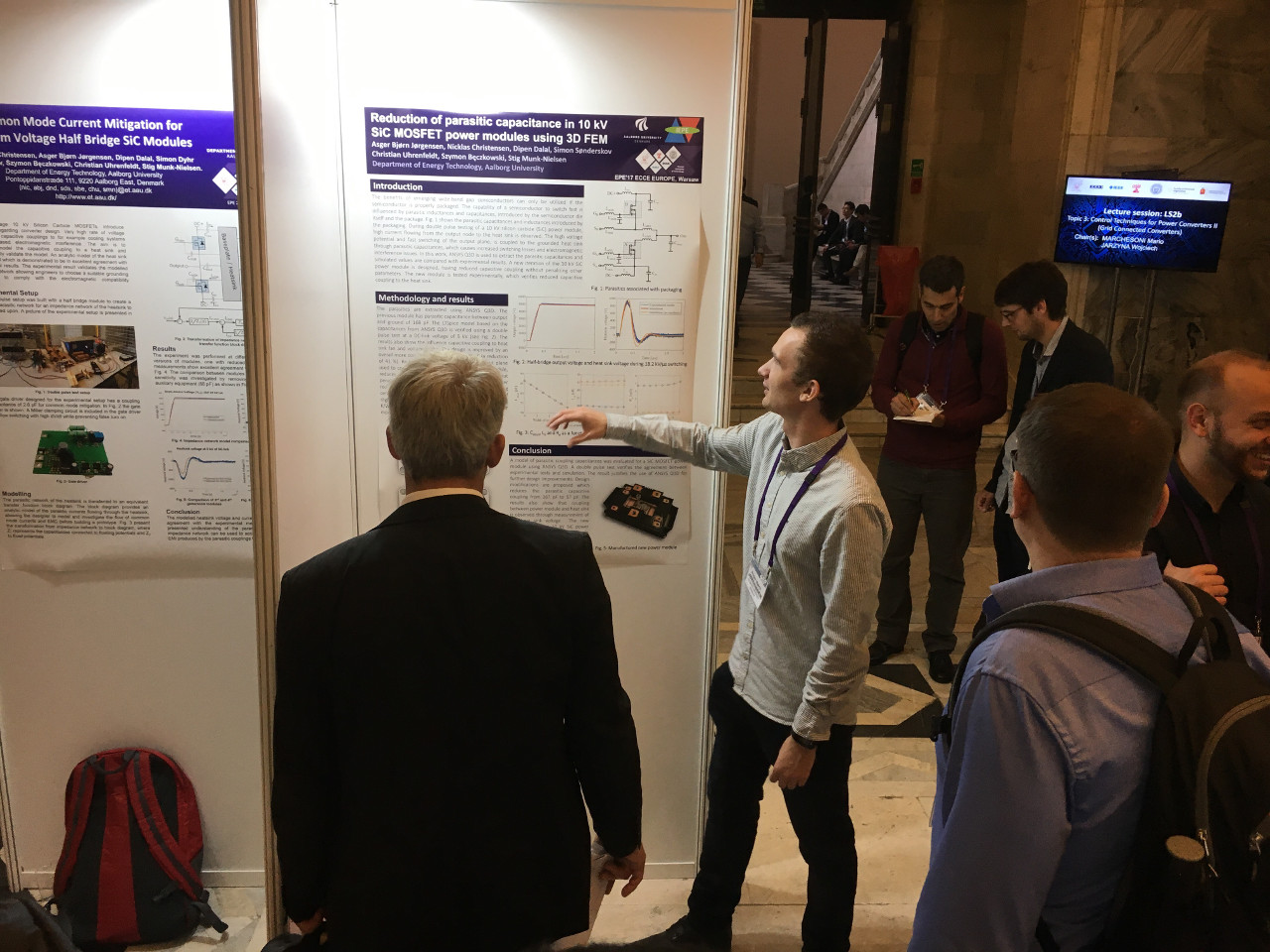

Last week i was at the 19th European Conference on Power Electronics and Applications, EPE'17 ECCE Europe held in Warsaw, Poland.

I presented the two following papers

A. B. Jørgensen et al., "Reduction of parasitic capacitance in 10 kV SiC MOSFET power modules using 3D FEM," 2017 19th European Conference on Power Electronics and Applications (EPE17 ECCE Europe), Warsaw, 2017, pp. P.1-P.8.

U. R. Nair, S. Munk-Nielsen and A. B. Jørgensen, "Performance analysis of commercial MOSFET packages in Class E converter operating at 2.56 MHz," 2017 19th European Conference on Power Electronics and Applications (EPE17 ECCE Europe), Warsaw, 2017, pp. P.1-P.9.

Access to both papers require a license, but do not hesitate to contact me if you would like to discuss the results.

How to easily repair consumer electronics

Written by Asger Bjørn Jørgensen, 2017-06-06

Failure of low price consumer electronics, such as monitors, PCs, audio amplifiers, is often caused due to cheap electrolytic capacitors. They might cause failure as early as within only 3 to 7 years of purchase. The electrolytic capacitor is part of the power supply unit in many of these electronic devices and ensures stable DC voltage levels of for instance 12 V or 3.3 V inside the device.Electrolytic capacitors are cheap and have a high capacitance to volume ratio, compared with other types of capacitors, making them advantageous for compact electronic devices in your household. However, the cheap electrolytic capacitors are filled with a liquid, which evaporates over time. This slowly increases the equivalent series resistance of the capacitor, leading to higher losses and eventually overheating of the capacitor. When this happens the pressure inside the capacitor increases, until the top "pops" off, evaporating the remaining liquid and causes the capacitor to fail. This "pop" of the top, ensures that the capacitor does not explode.

However, if the capacitor is the cause of failure, and did not harm the rest of the power supply, it is easy to fix by just replacing these capacitors. I've done this with an old Hanns-G monitor. Whenever i tried to start it, the "power LED" would flash for a second, and then the monitor would go off again.

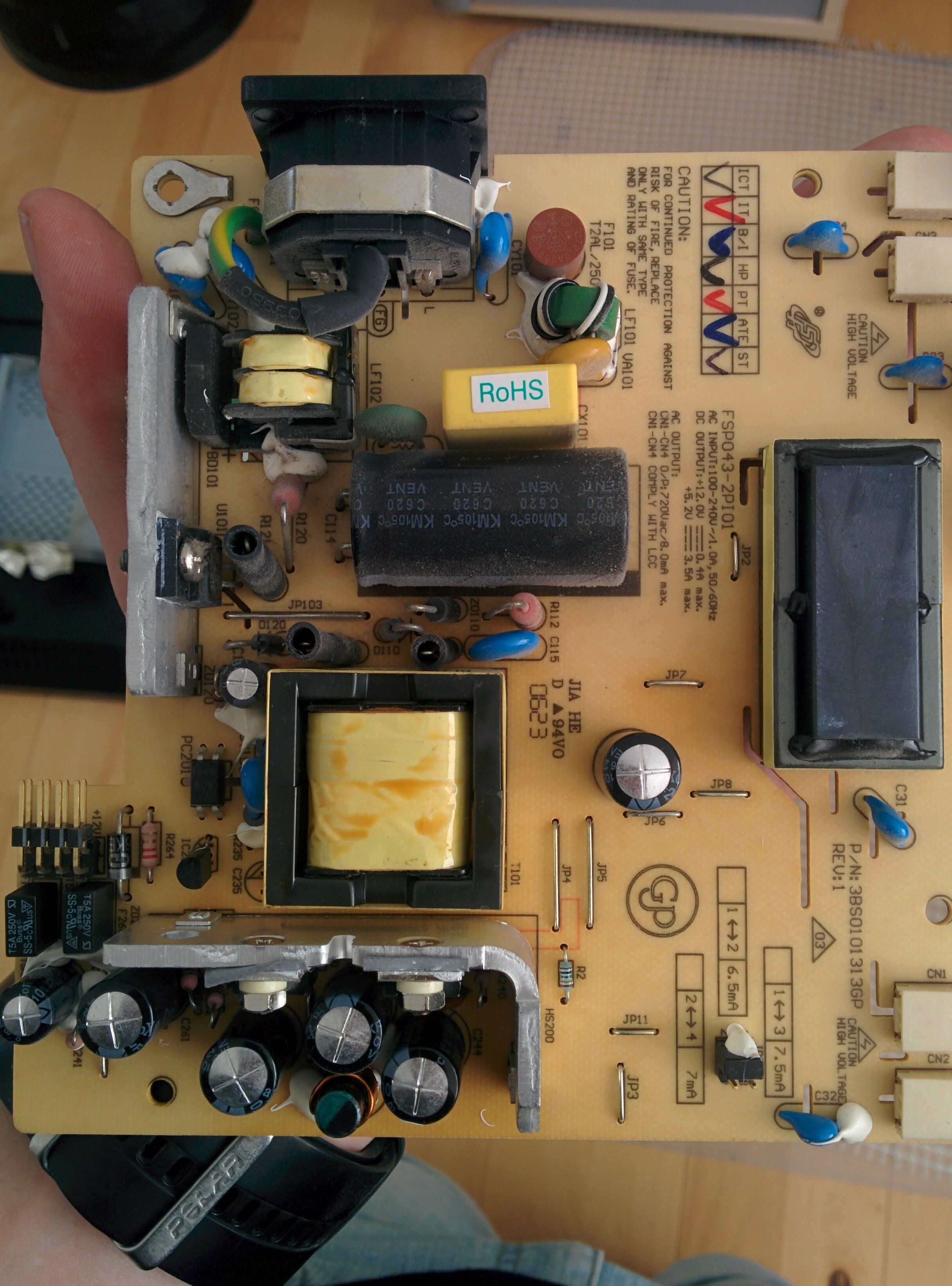

I popped off the plastic framing on the backside, and found a metal casing with two PCBs. One with the power supply unit and another with the video card doing all the processing, as shown in Fig. 1.

Fig. 1: Metal enclosure on the back holds both power supply and video PCB boards.

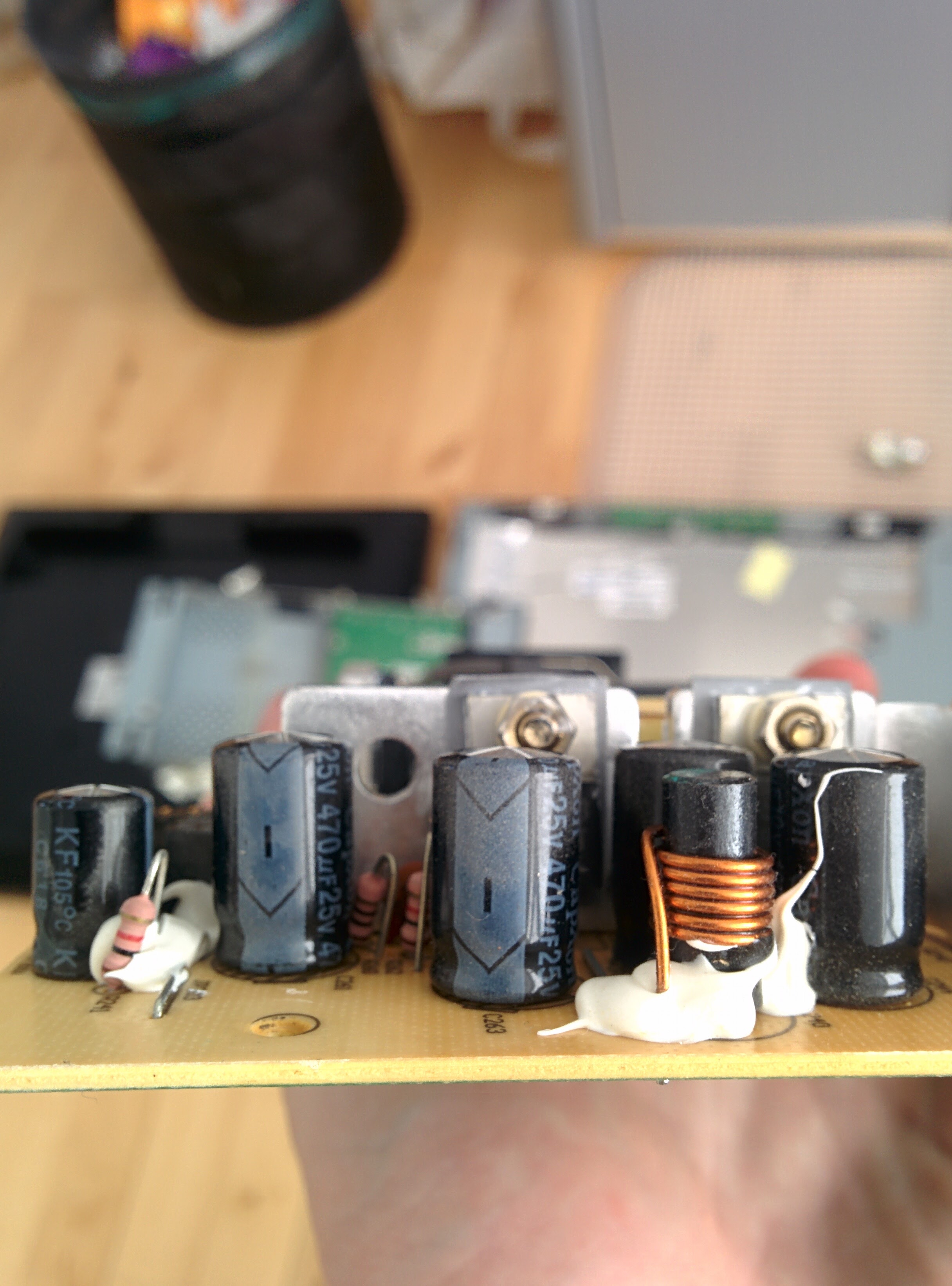

Disassembling the two boards i located the power supply unit of the two. I located all the electrolytic capacitors, as shown in the Fig. 2. You can clearly see how the top of the capacitor is popped up.

Fig. 2: (left) Electrolytic capacitors are located in the bottom left corner (right) side-view showcasing the "pop off" effect of a failed capacitor.

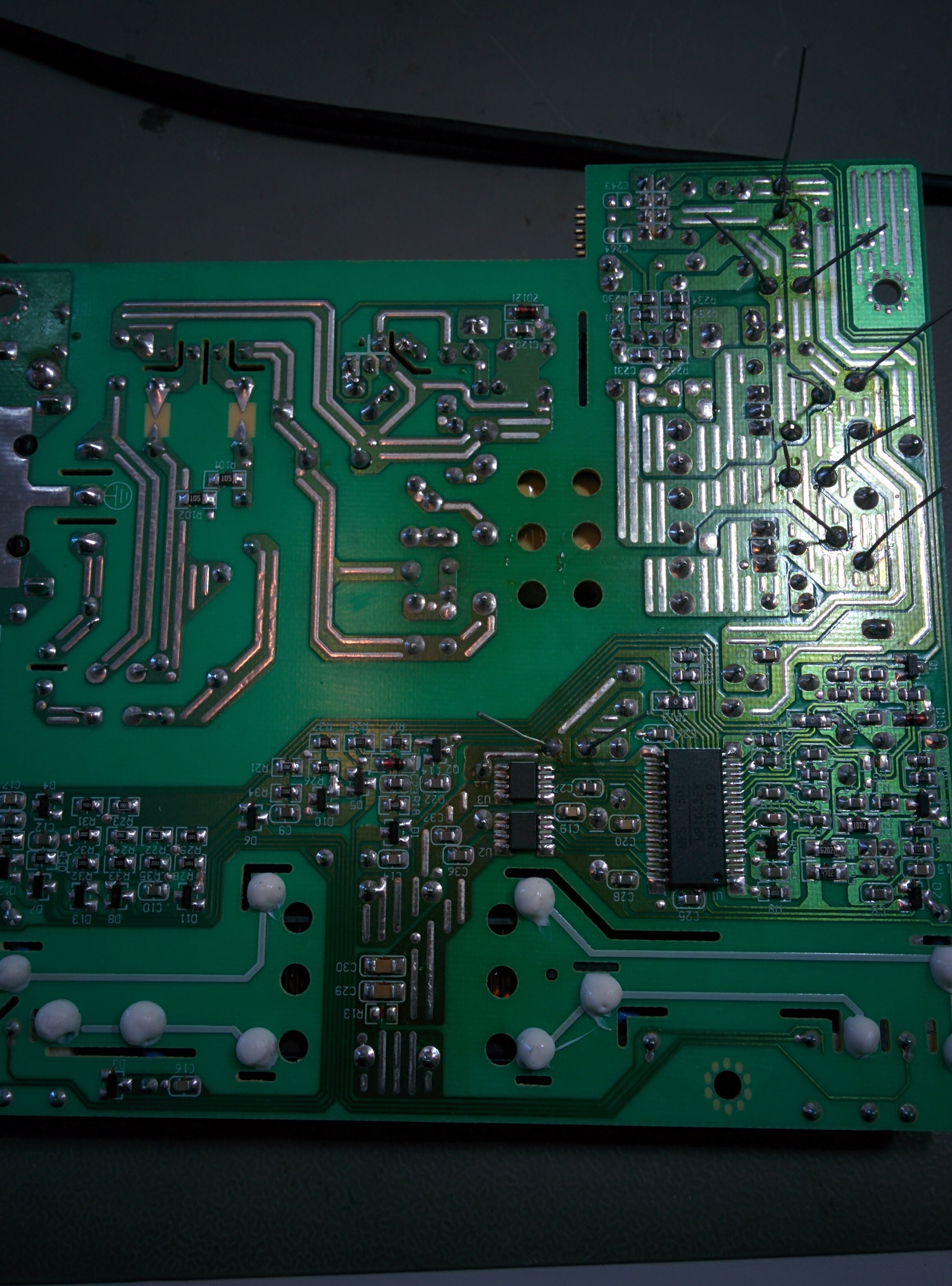

I desoldered all of the electrolytic capacitors and soldered on new ones. Most importantly remember the orientation of the electrolytic capacitor (they have a plus and minus, which must not be reversed!) and choose a capacitor with same or higher voltage rating. For its capacitance value you should be safe by choosing one with the same or larger, but it might not prove fatal even if it is even a little bit smaller in capacitance value.

Fig. 3: Remember orientation, voltage rating and capacitance value of new capacitors!

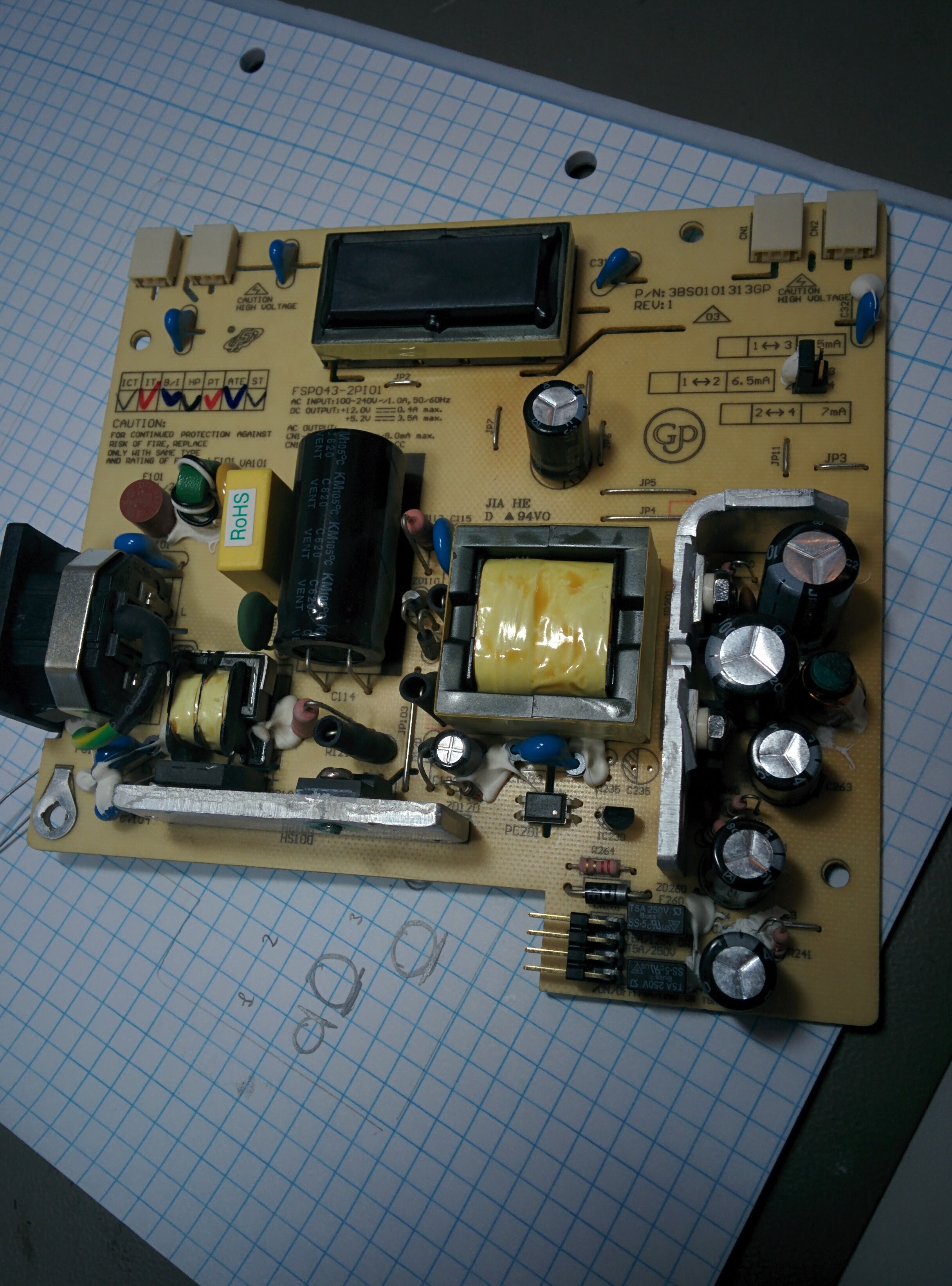

Fig 4. shows the power supply with replaced electrolytic capacitors. Compared with Fig 2., it is noticeable that the top of the capacitor is now flat.

Fig. 4: Power supply board with new electrolytic capacitors.

I assembled everything back together it worked like a charm.

Show older